VAN DER LEE Turbo Systems is a full service provider of design, development and production of highly reliable cost efficient turbocharger solutions excelling in branch leading lead-times

Custom designed systems to fit your specific application needs. With the abibility to combine our designs with the best suited OEM-components we guarantee optimal quality and best value.

We design, develop and produce Turbochargers for a wide variety of applications and a diverse scope of requirements. Enhancement of performance, reduction of emissions or optimisation of fuel consumption, whatever your specific requirement is we are able to deliver the best solution.

- Proven OEM quality and performance

- Technical innovations and optimal flexibility

- One-off applications to full volume series under QMS

Design process

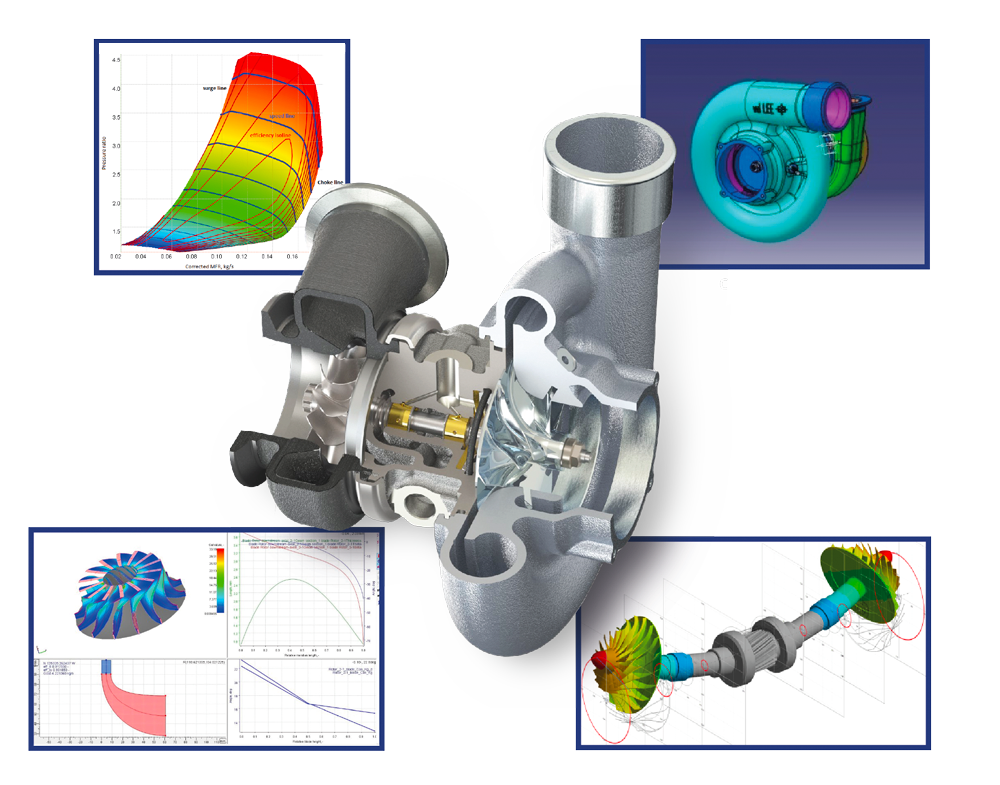

Designing a high-performance turbocharger involves a complex and iterative process that takes into account a multitude of factors. The design of a turbocharger needs to balance factors such as airflow capacity, pressure ratios, and rotational speeds to ensure optimal performance.

The design process typically begins with defining the specific requirements and constraints of the turbocharger, the target power output, engine displacement, and desired boost pressure. Once these parameters are established, the design team can begin to develop a preliminary design that takes into account the aerodynamics of the compressor and turbine components, as well as the material and manufacturing considerations.

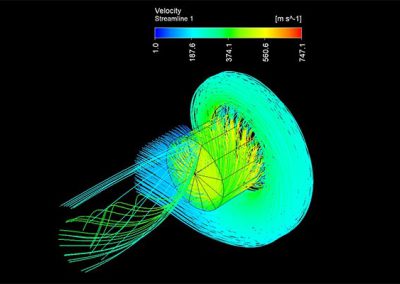

The next step is to simulate the performance of the turbocharger using computational fluid dynamics (CFD) software, which allows the team to test and optimize the design for maximum efficiency and performance.

This process involves refining the shape of the compressor and turbine blades, adjusting the angle and curvature of the diffuser and nozzle, and optimizing the overall flow path of the air through the system.

Once the design has been optimized using CFD, physical prototypes can be created using 3D printing or other rapid prototyping techniques. These prototypes can be tested on a flow bench or dynamometer to verify their performance and make any necessary adjustments.

Ultimately, the design process for a high-performance turbocharger is a combination of art and science, requiring a deep understanding of aerodynamics, materials science, and manufacturing processes. With careful attention to each step of the process, a well-designed turbocharger will provide a significant boost in engine performance and efficiency.